I-Form spinout Infraprint 3D printing with the power of the sun

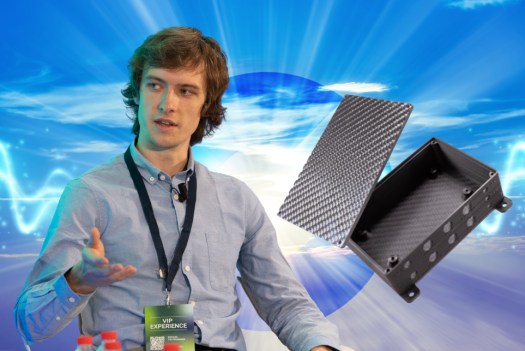

Former PhD Student and postdoc researcher Dr Andrew Dickson has become the latest success story to arise from I-Form – the SFI Research Centre for Advanced Manufacturing – with the recent establishment of his deep tech start-up company Infraprint in January this year.

Armed with a novel technology set to disrupt the global manufacturing industry, Infraprint can 3D-print polymer parts which are significantly stronger than any other system currently on the market.

This is achieved through Infraprint’s patent-pending TRAAM technology (Thermal Radiation Assisted Additive Manufacturing), which uses infrared to apply heat during the 3D printing process. Compared to some existing systems which use fan ovens, this technology is far more energy efficient. Infraprint’s desktop-sized system also comes in at a more appealing price point than many industrial-sized 3D printing systems, with lower upkeep costs. The Infraprint system is effectively a ‘factory in a box’.

Infraprint has already produced several successful trial products within the aerospace and medical sectors, with vast potential across many other applications still to be uncovered.

Andrew, Infraprint’s co-founder and chief technology officer, commented on his hopes for the company, and the future of 3D printing.

“3D printing is one of the fastest growing manufacturing technologies. It is already saving materials, cost, time and enabling local manufacturing of products all over the world. Infraprint is bringing rapid, reliable, high strength and high performance polymer 3D printing into the Space and Aerospace sectors, harnessing our patented printing technology. Infraprint has ambitions to be the go-to manufacturer for 3D printing of high performance polymers.”

Professor Denis Dowling, I-Form Centre Director, outlined that:

“Infraprint is an example of how I-Form’s research on additive manufacturing has led to the successful establishment of a start-up company. There is a clearly demonstrated need from industry end users for Infraprint’s deep knowledge of 3D printing processes, as well as their expertise in identifying suitable polymers and composites to meet what can often be demanding engineering applications.”

Infraprint’s story exemplifies how funding from Science Foundation Ireland supports research talent and technological innovation, providing a pathway for the formation of new Irish companies, creating new jobs.

Infraprint’s cutting edge work has also seen them granted pre-seed funding from Enterprise Ireland, helping them to move towards commercialisation. Support at these early stages is critical for tech startups to survive, and ensure their innovative products and services are not lost to the economy.

Offering their customers contract manufacturing and consultancy services, Infraprint is seeking partners who share their vision for the future of sustainable manufacturing. Contact Infraprint HERE to discuss how they can help to elevate your product into the digital age.

It is exciting to envisage what the coming years might have in store for Infraprint, as they lead the way towards a sustainable and efficient manufacturing future.